Mast 3: Electrical connections lights.

In the mast are 23 led-lights and each one needs a wire for the power. Not every light burns during the hole time, some only need to work if the crane is working or when towing, some are reserve lights.

The mast is made from a brass tub with a inner diameter of 5 mm and this makes it impossible to use normal isolated wires and that is the reason for using the 0,2mm solderable enamelled soft copper wire. This makes it easier to get all those wires through the tubes.

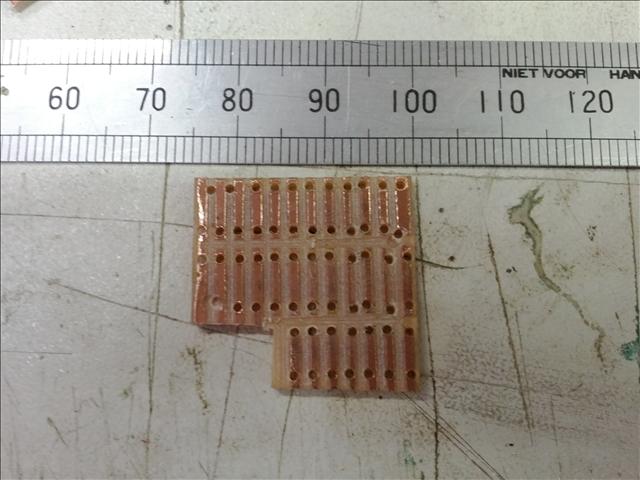

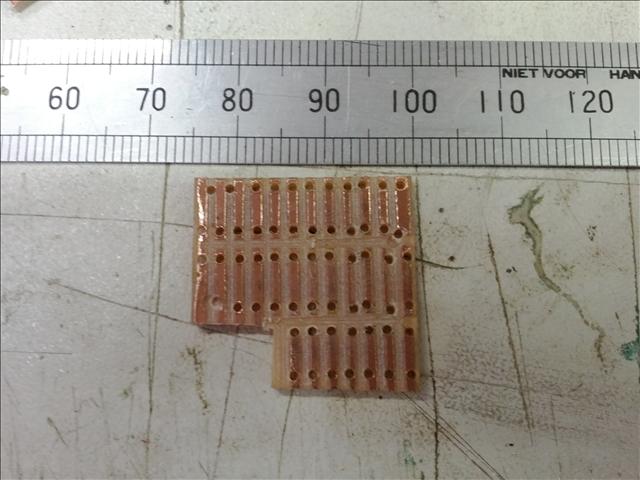

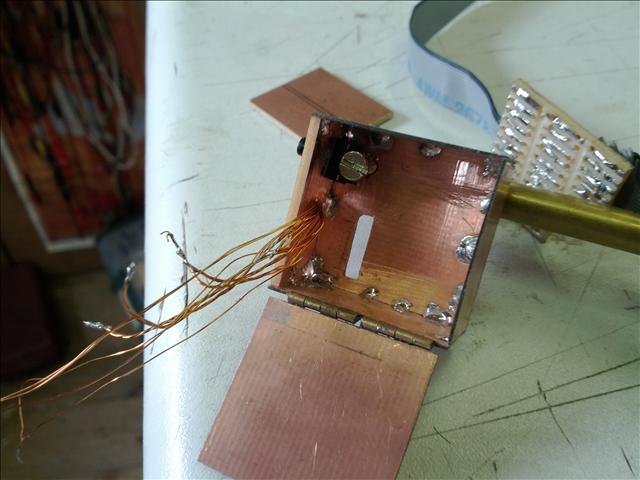

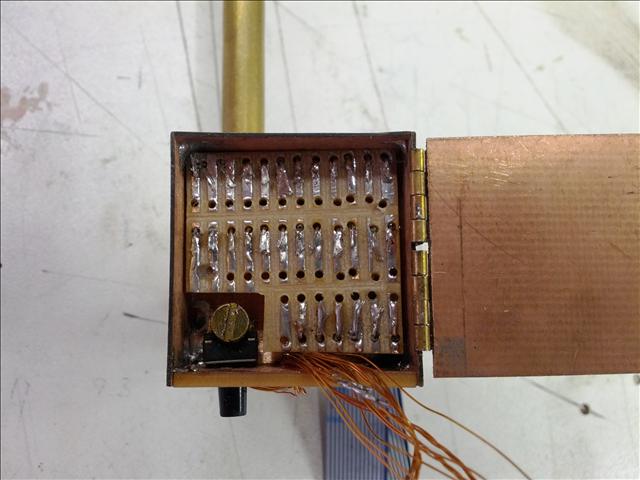

Because the mast is moveable I made a e-cabinet at the foot of the mast in wich all the copper wires are connected to a circuit board and from there 2 flatcables take over. The circuit board is made with the proxxon milling machine.

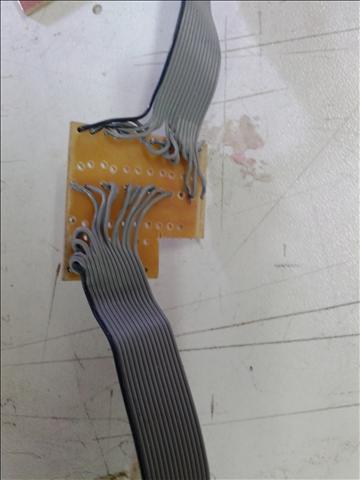

The circuit board.

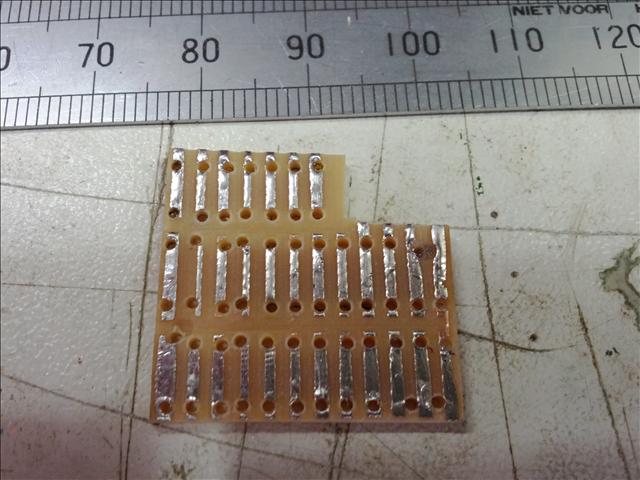

Here the everything is soldered

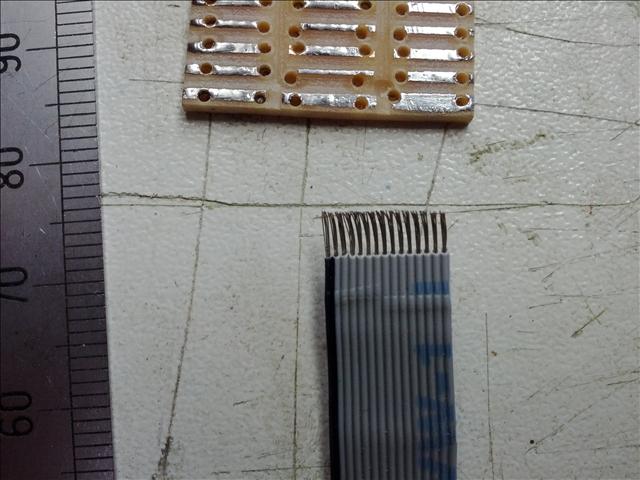

1 of the 2 flatcables.

Both the flatcables are soldered, the copper wires need to go in the free holes.

The e-cabinet is made with 0,4 mm circuitboard and mounted to the foot of the mast, this makes it a lot easier to get all the wires to the lights. On the left topside there is the endswitch to stop the motor when the mast stands upright. All the signals and currents will go through the 2 flatcables into the wheelhouse.

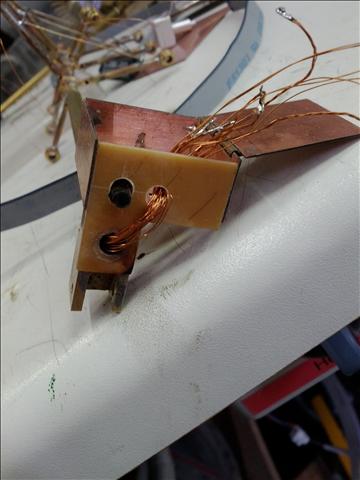

The bottomplate of the e-cabinet is soldered to the foot of the mast, you can see the copper wires and the endswitch.

Here is the print with the flatcables inside the e-cabinet, the wires of the lights need to be soldered but this will be done after the mast is painted.