Wheelhouse.

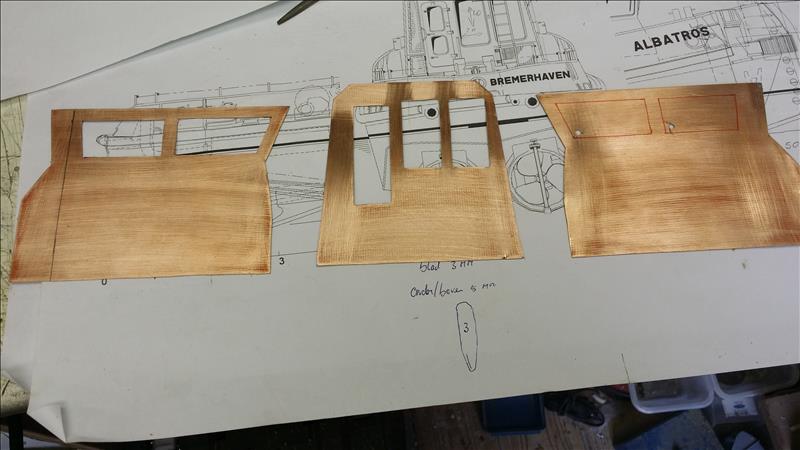

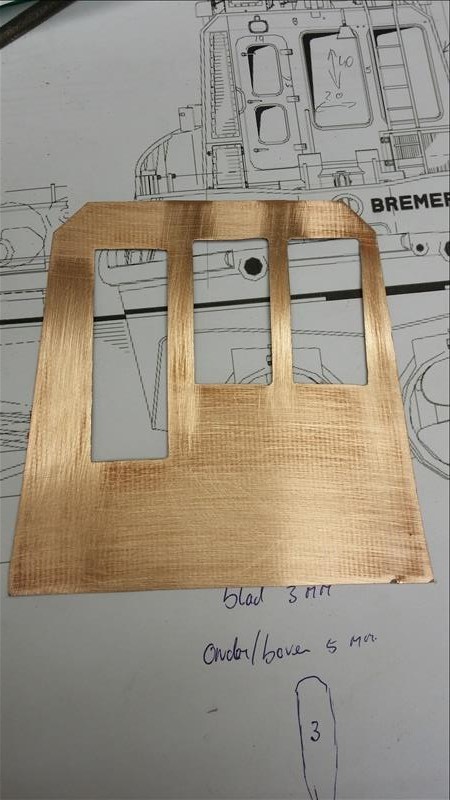

At first I wanted to make the wheelhouse from polystyrol sheets but after making the sidewalls I didn't find it very stabil and so I got a look into my material stock and found a 0.5 mm circuitboard sheet. Working with circuitboard sheets is something I to do, just solder it together and no waiting for glue to get cured. Also you get a strong watertight and smooth finish, a disadvantage is the visible solder joint if you don't work properly.

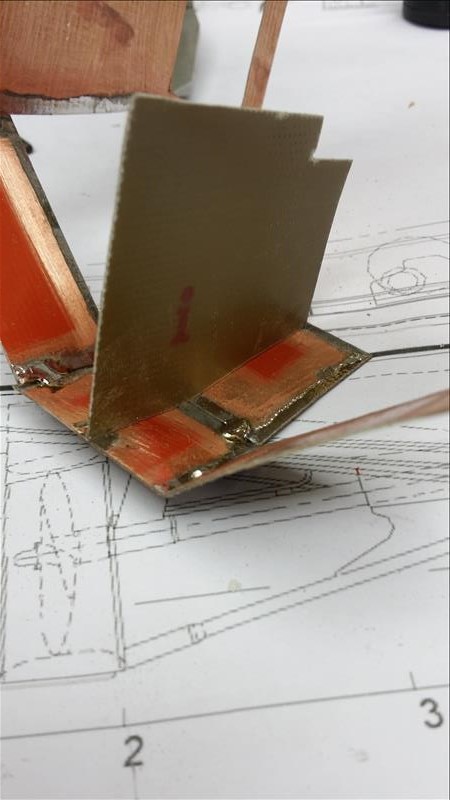

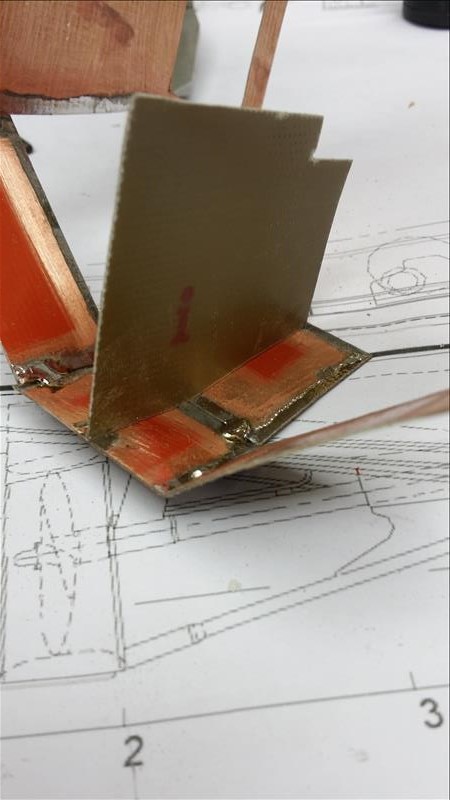

A part with the correct angle helps during soldering

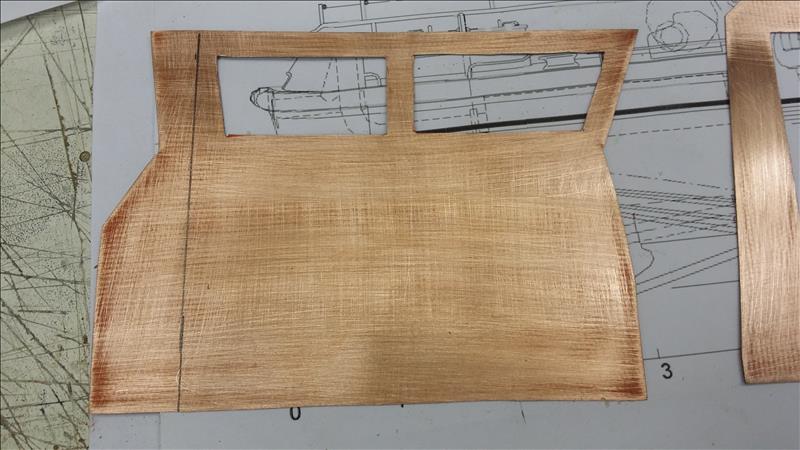

The circuitboard I use for this wheelhouse has a photo sensitive layer on top wich make drawingon it with a marker easier. After marking just cut and sand it and it's ready to solder. The windows are cut out with the jigsaw and filed to the right size.

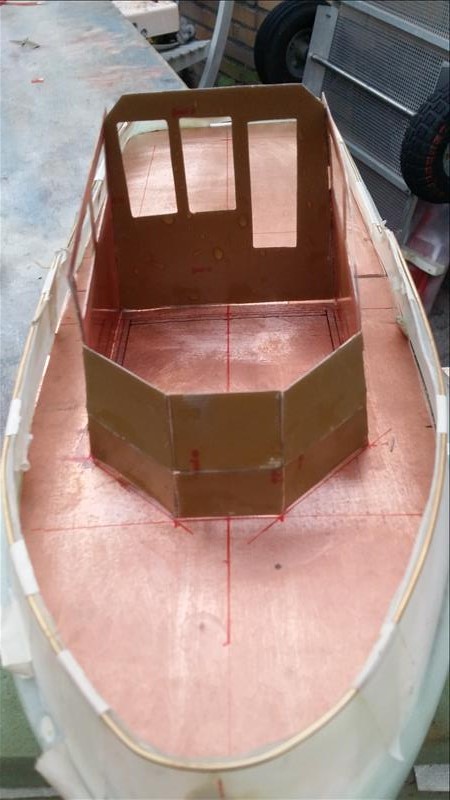

Once the sidewalls were ready they are soldered together. The outlines of the wheelhouse are drawn on the deck so for the next pieces it was just measure them and cut to size before soldering.

The front exist of several panels under different angles so every plate needs to be made by measure it on the spot it needs to come. The only thing that was determent were the angle and length.

The two bottom rows went very well and quick, to make the windows I used brass wires. I bent them in the right angle and lenght to get a clear shape. The wires are also a help in soldering the plates together.