Hull - XPS foam

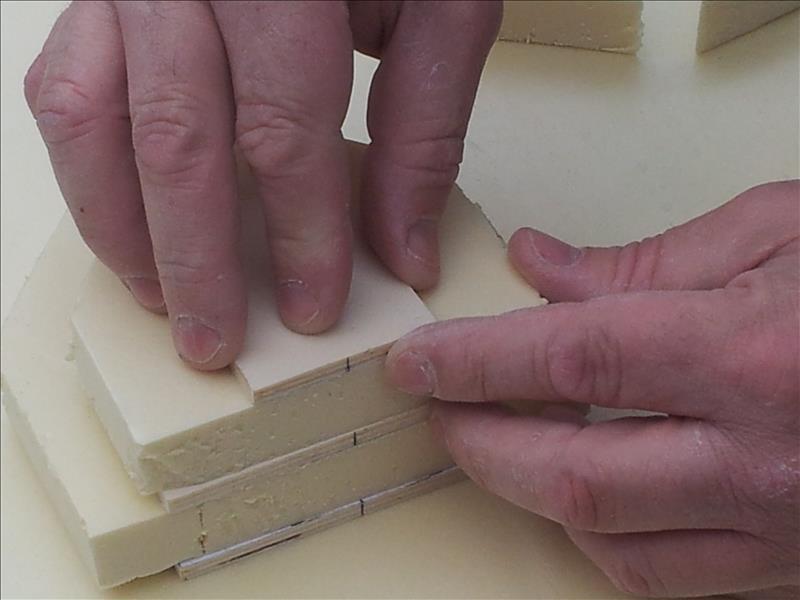

After the ribs are glued I cut the roughly cut XPS foam in two parts and glued them between the ribs with kit, this works good and the connection is very strong. The XPS foam is still bigger than the ribs.

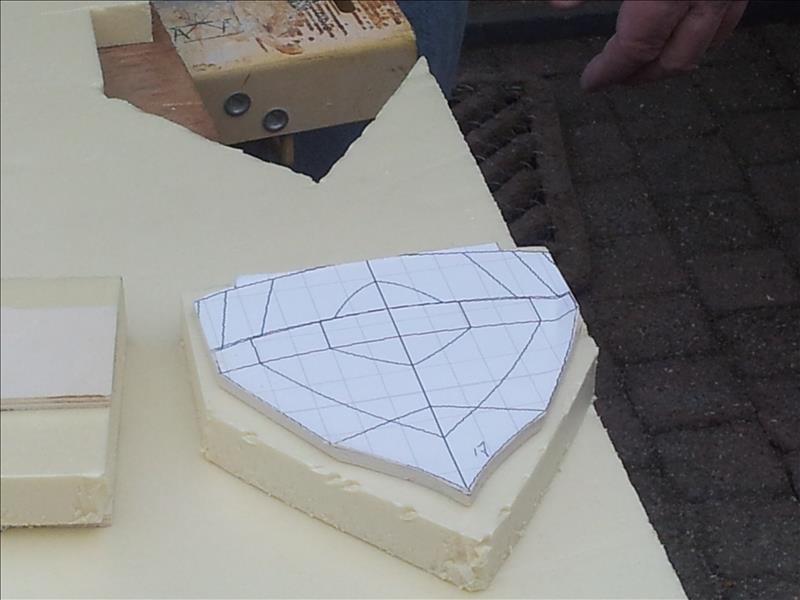

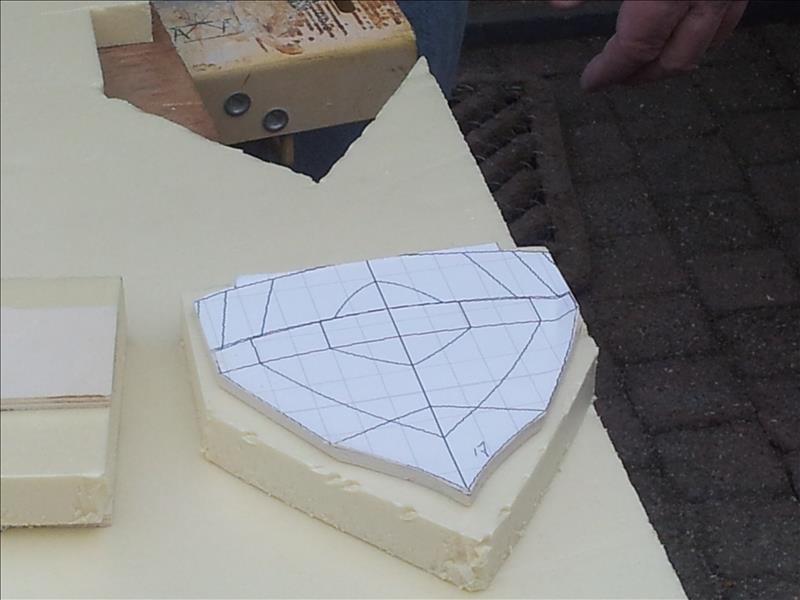

The roughly cut XPS foam.

Stacking the foam and ribs gives you a clear image of what the final shape will be.

The XPS foam is glued.

AOn the back and front there is a extra piece of foam glued to get the round shape.

The hull ....

The foam is sanded down to the ribs, only the backside needs to be done.

Next step is cover this all with polyester putty to get a strong wall on wich there will be details placed to get a complete hull for the mould.